Battery protection measures for electric vehicles

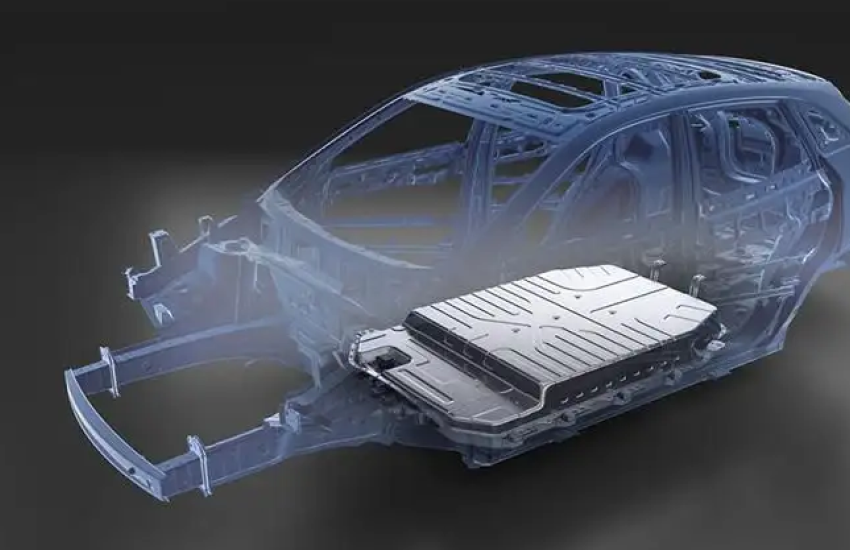

Enclosure protection: To prevent air from entering, lithium batteries are sealed in closed containers, and stainless steel and aluminum alloy enclosures are usually used to prevent external damage. For example, Tesla's electric vehicles even use titanium alloy protective plates to prevent damage to battery containers in use, especially in traffic accidents.

Diaphragm blocking protection can not only prevent external force damage, but also prevent damage from inside the battery.

Generally, in order to prevent short circuit caused by direct contact between the positive and negative electrodes of the battery, there will be a layer of diaphragm in the battery, which will separate the positive and negative electrodes on the one hand and allow charged ions to pass through on the other.

However, in lithium batteries, the diaphragm also performs another protective function. When the battery temperature is too high, the gap of the diaphragm will automatically close, making it impossible for lithium ions to pass through, thus terminating the reaction of the entire battery. Therefore, the problem that the battery sealing structure is damaged due to the high temperature of the battery, which makes the electrolyte in the battery vaporize to generate high pressure.

Overcharge voltage protection not only prevents the air from being blocked, but also prevents the metal lithium from leaking out of the electrode.

Scientists store and lock the lithium metal formed in the charge discharge process through the nano pores of electrode materials and the material lattice mechanism.

In this way, even if the battery shell is broken and oxygen enters, oxygen molecules will be too large to enter these small storage cells, thus avoiding spontaneous combustion.

However, using too high voltage or charging for too long after full charge will cause very dangerous damage to the lithium battery.

After the charging voltage of the lithium battery is higher than the rated voltage (generally 4.2V), if the battery continues to be charged, since the storage cell of the negative electrode has been filled with lithium atoms, the subsequent lithium ions will accumulate on the surface of the negative electrode material. These lithium ions will form electron transfer due to polarization, forming metal lithium, and dendritic crystals will grow from the anode surface to the direction of lithium ions.

On the one hand, these metal lithium without electrode protection are extremely active and prone to oxidation reaction and explosion. On the other hand, the lithium metal crystal formed will break through the diaphragm, making the positive and negative poles short circuited, thus causing short circuit and high temperature. At high temperatures, materials such as electrolyte will crack to produce gas, causing the battery shell or pressure valve to bulge and crack, allowing oxygen to enter and react with lithium atoms stacked on the surface of the negative electrode, thus causing explosion.

When charging the lithium battery, be sure to set the upper voltage limit and overcharge protection. Such protection circuits are installed in lithium batteries produced by regular battery manufacturers. When the voltage exceeds the standard or the battery is fully charged, the power will be cut off automatically.